How is ammonia shaping trade and supply chains in the Middle East and Southwest Asia?

Ammonia, a cornerstone of the global chemical industry, holds a pivotal role in West Asia"s trade markets, particularly the Middle East. With its chemical formula NH3, ammonia is essential in producing fertilizers, industrial cleaning agents, and refrigeration systems. The Southwest Asia ammonia market has witnessed steady growth, fueled by increasing agricultural demand and the region"s strategic position in global trade. Middle Eastern countries, rich in natural gas—a primary feedstock for ammonia production—have emerged as leading exporters, ensuring a consistent supply to agricultural and industrial sectors worldwide. As a commodity, ammonia"s trade dynamics in the Middle East are driven by its applications in fertilizers and pesticides, critical for regional and global food security. Verified exporters and importers leverage platforms like B2B marketplaces to streamline ammonia transactions. Such platforms enhance supply chain solutions by connecting buyers and sellers, offering market insights, and ensuring transparency. Regional product listings for ammonia are bolstered by the Middle East’s vast petrochemical resources, which also feed parallel markets in sulfuric acid, phosphoric acid, chlorine, and nitrogen.

Sulfuric acid and phosphoric acid, essential in fertilizer production, complement ammonia"s market positioning. Meanwhile, industrial gases like oxygen, nitrogen, and chlorine—integral to the Middle East"s oil and gas sectors—further demonstrate how interconnected chemical trade is across West Asia. The trade of detergents and hygiene products also benefits from ammonia derivatives, showcasing its versatility in consumer industries. Aritral, an AI-driven B2B platform, facilitates ammonia trade by simplifying international transactions, ensuring verified profiles, and delivering tailored market insights. It bridges global supply chains with features like AI-powered marketing and direct buyer-seller communication, positioning itself as a vital tool for commodity traders in the Middle East. "

-

Yemen

Ben Naaman Lamasalizamat Almuamalat Altaalimiyya WalSina'iyya BiAjhizatiha Wamawadiha Alkimiyaiyya

Yemen

Ben Naaman Lamasalizamat Almuamalat Altaalimiyya WalSina'iyya BiAjhizatiha Wamawadiha Alkimiyaiyya

#Everyone has everything related to laboratories: ✅Models in all shapes ✅Tools and experimental devices ✅#Educational_Toys ✅#Glassware ✅#Chemicals ✅#P...Details

-

Nasrin Mojarrad 1 months ago

Nasrin Mojarrad 1 months ago Iran

Trading House Mojarrad

Iran

Trading House Mojarrad

Trading house me peresent all selected goods with the lowest price and the highest quality to domestic and international markets.Details

-

Homayoun 2 months ago

Homayoun 2 months ago Afghanistan

Sulfuric Acid

Afghanistan

Sulfuric Acid

Buyer of sulfuric acidDetails

-

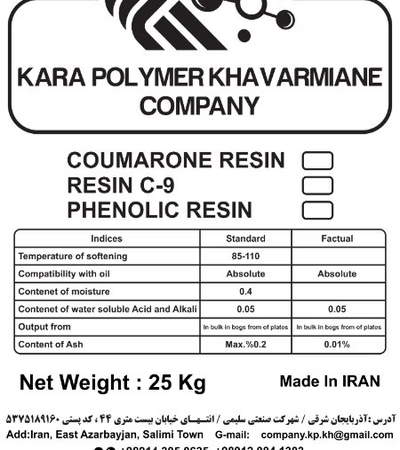

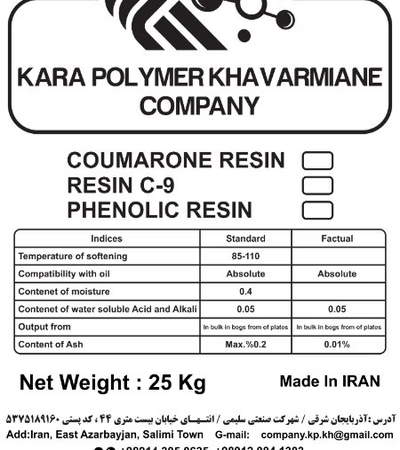

Kara Polymer Khavarmiyaneh 2 months ago

Kara Polymer Khavarmiyaneh 2 months ago Iran

Various Types of Coumarone Phenolic Petro Resin

Iran

Various Types of Coumarone Phenolic Petro Resin

Manufacturer of various types of petroleum-based coumarone phenolic resins for rubber manufacturing purposesDetails

-

Lawyer. Manar R R 2 months ago

Lawyer. Manar R R 2 months ago Syria

Permanent hair dye & Hair meshes & Hair mask

Syria

Permanent hair dye & Hair meshes & Hair mask

Dear SirsWe are producing permanent hair dye & Hair meshes & Hair masksWe are too interesting to exchange positive business partnership abroadFurtherm...Details

-

Qaranfil. Ir 2 months ago

Qaranfil. Ir 2 months ago Iran

Dates

Iran

Dates

All chemicals and laboratory machinery and equipment produced in Iran are available. We can also procure Turkish chemicals and products upon order. Dr...Details

-

عالم الكيماويات والمستلزمات الطبية 2 months ago

عالم الكيماويات والمستلزمات الطبية 2 months ago Yemen

World of Chemicals and Medical Supplies

Yemen

World of Chemicals and Medical Supplies

Welcome to the World of Chemicals, where we offer you a wide range of high-quality chemical and medical products to meet your needs: We have a variety...Details

-

Omar Rabie 2 months ago

Omar Rabie 2 months ago Egypt

Animal Feed

Egypt

Animal Feed

Poultry Feed Diamond Feed Sheep and Goat Feed Camel FeedDetails

-

Steelmangases Pvt Ltd 2 months ago

Steelmangases Pvt Ltd 2 months ago India

Chlorine Gas,Sodium Hypochlorite,Liquor Ammonia / Ammonia Solution

India

Chlorine Gas,Sodium Hypochlorite,Liquor Ammonia / Ammonia Solution

Our quality products are available at competitive prices and you can easily get in touch with us to buy the best products easily. Abbas Vora +91 76...Details

-

Arbenco Petrochemical Company 2 months ago

Arbenco Petrochemical Company 2 months ago Bahrain

I have 50 thousand tons of methanol. Do you buy or do I have a customer for them?

Bahrain

I have 50 thousand tons of methanol. Do you buy or do I have a customer for them?

For sale: 50 thousand barrels of methanol, phone number: 0097339211616Details

-

Ammonia Trade Dynamics in the Middle East and West Asia

Ammonia, a cornerstone of the global chemical industry, holds a pivotal role in West Asia"s trade markets, particularly the Middle East. With its chemical formula NH3, ammonia is essential in producing fertilizers, industrial cleaning agents, and refrigeration systems. The Southwest Asia ammonia market has witnessed steady growth, fueled by increasing agricultural demand and the region"s strategic position in global trade. Middle Eastern countries, rich in natural gas—a primary feedstock for ammonia production—have emerged as leading exporters, ensuring a consistent supply to agricultural and industrial sectors worldwide. As a commodity, ammonia"s trade dynamics in the Middle East are driven by its applications in fertilizers and pesticides, critical for regional and global food security. Verified exporters and importers leverage platforms like B2B marketplaces to streamline ammonia transactions. Such platforms enhance supply chain solutions by connecting buyers and sellers, offering market insights, and ensuring transparency. Regional product listings for ammonia are bolstered by the Middle East’s vast petrochemical resources, which also feed parallel markets in sulfuric acid, phosphoric acid, chlorine, and nitrogen.

Sulfuric acid and phosphoric acid, essential in fertilizer production, complement ammonia"s market positioning. Meanwhile, industrial gases like oxygen, nitrogen, and chlorine—integral to the Middle East"s oil and gas sectors—further demonstrate how interconnected chemical trade is across West Asia. The trade of detergents and hygiene products also benefits from ammonia derivatives, showcasing its versatility in consumer industries. Aritral, an AI-driven B2B platform, facilitates ammonia trade by simplifying international transactions, ensuring verified profiles, and delivering tailored market insights. It bridges global supply chains with features like AI-powered marketing and direct buyer-seller communication, positioning itself as a vital tool for commodity traders in the Middle East. "

-

Chlorine Trade in West Asia: Market Dynamics and Applications

Chlorine, a vital chemical element, plays a pivotal role in various industrial applications and commodities trade across West Asia and the Middle East. As part of the chlor-alkali production chain, chlorine is essential in manufacturing products such as detergents, fertilizers, pesticides, and industrial chemicals, supporting key sectors like agriculture, healthcare, and petrochemicals. The Middle East’s abundant oil and gas reserves fuel chlorine production via ethylene dichloride units, creating robust trade opportunities for regional exporters and importers. The chlorine market in Persian Gulf countries benefits from growing infrastructure, which includes verified exporters and importers facilitated by platforms like Aritral. Such platforms enhance supply chain solutions by offering regional product listings, connecting buyers and sellers, and providing market insights. Chlorine, available in gas, liquid, or solid forms, is traded extensively for its applications, including water purification, disinfection, and synthesis of chemical intermediates. Its diverse uses make it a high-demand commodity in Southwest Asia. In synergy with other chemicals like sulfuric acid, phosphoric acid, nitrogen, and ammonia, chlorine supports the manufacturing of detergents, fertilizers, and pesticides.

Verified suppliers and buyers leverage business networking platforms to bridge global supply chains for agricultural and industrial needs. Additionally, the trade advertising platform enables businesses to explore opportunities, optimize pricing, and meet compliance standards in cross-border transactions. With rising imports and exports, the Middle East chlorine market sees competitive pricing influenced by large-scale production units and dynamic trade dynamics. Chlorine’s role in the regional economy is complemented by other commodities vital to industrial and agricultural growth. Aritral simplifies international trade processes by providing AI-powered tools for product listing and marketing, ensuring seamless business operations in the chlorine sector and beyond.

-

Exploring the Detergent Trade in West Asia and the Middle East

The detergent market in West Asia and the Middle East is witnessing significant growth, driven by increasing demand for household cleaning products and hygiene solutions. The trade of soap, detergents, washing liquids, and products for dishwashing and clothing care forms a pivotal part of the region"s commodity trade. Leading regional B2B marketplaces and trade platforms are focusing on connecting verified exporters and importers within this sector, fostering efficient supply chain solutions. Key raw materials such as sulfuric acid, phosphoric acid, and ammonia play an integral role in detergent manufacturing. Sulfuric acid, widely used in cleaning agents, is a cornerstone of the Middle Eastern chemicals market, where manufacturers and exporters actively trade this commodity. Similarly, phosphoric acid, essential for producing detergents and fertilizers, is frequently traded in Southwest Asia. Verified buyers and sellers in the region leverage platforms that provide market insights and connect stakeholders to optimize trade volumes. Moreover, the rise of industrial oxygen and nitrogen gas markets in the Middle East underscores broader chemical trade dynamics.

Industrial oxygen facilitates manufacturing processes, while nitrogen gas finds applications in cleaning products, making both critical to the regional supply chain. The export of cosmetic products from Asia complements the detergent trade, highlighting opportunities for businesses to diversify their portfolios. Regulatory compliance, including adherence to international standards (e. g. , HS codes 340111, 340120, 340211), is essential for businesses aiming to scale internationally. Platforms like Aritral enhance this ecosystem by offering product listings, AI-powered marketing, and verified trader profiles. By streamlining communication and providing actionable insights into commodity markets, such platforms empower businesses to thrive in the Asian detergent and hygiene market. "

-

Fertilizers and Pesticides Trade Dynamics in the Middle East

Fertilizers and pesticides play a pivotal role in the agricultural supply chain, especially in the Middle East and West Asia where trade in agricultural chemicals is a growing industry. With the increasing demand for sulfuric acid, phosphoric acid, ammonia, nitrogen, and chlorine in fertilizer and pesticide production, these substances are shaping regional and global trade dynamics. West Asia, in particular, is a key player in the export and import of these chemicals, driven by its strategic location and robust commodity trade platforms. Sulfuric acid, widely used in phosphate fertilizer production, sees significant trade activity in the Middle East through verified exporters and importers. Similarly, phosphoric acid and ammonia are critical to the fertilizer sector, with Southwest Asia showing sustained demand. Ammonia is not only vital in fertilizer production but also plays a crucial role in driving regional supply chains. Oxygen and chlorine, though primarily known for industrial and medical applications, have increasing relevance in agricultural chemical processes. The West Asian nitrogen gas market is also expanding, aiding in the synthesis of key fertilizers.

Meanwhile, the detergent market, closely tied to agricultural chemicals like phosphates, is shaping regional economies and supply chains. Platforms like Aritral enable businesses to connect with verified suppliers, buyers, and manufacturers to explore market opportunities for fertilizers, pesticides, and other agricultural chemicals. Through AI-driven product listings, trade advertising, and market insights, such platforms streamline the process of bridging global supply chains for agricultural needs across West Asia and the Middle East.

-

Nitrogen Trade Dynamics in West Asia and Middle East Markets

Nitrogen, a critical industrial and agricultural commodity, plays an essential role in the Middle East and West Asia’s trade dynamics. As the backbone for fertilizers, pesticides, and industrial chemicals, nitrogen is integral to the region’s agricultural and manufacturing sectors. Industrial nitrogen, a chemically inert gas, is widely used in applications such as food preservation, electronics manufacturing, and medical technologies. Its versatility makes it a key player in supply chains across West Asia. The import-export trade of nitrogen gas has witnessed steady growth, driven by the demand for agrochemicals, including ammonia and phosphoric acid derivatives used in fertilizers. The Middle East nitrogen market is shaped by its integration into regional supply chains, with verified exporters and importers connecting through platforms like Aritral. These B2B marketplaces offer regional product listings and market insights, enabling efficient trade and logistics management. The commodity trade in West Asia also highlights sulfuric acid and chlorine as vital chemicals alongside nitrogen.

Sulfuric acid plays a critical role in fertilizer production, while chlorine is essential for water treatment and various industrial applications. Both chemicals, alongside nitrogen, are reshaping the trade landscape by meeting the growing demands of agriculture and industrial sectors. Market trends indicate that nitrogen’s demand will continue to rise, particularly in Persian Gulf nations, where agricultural productivity is heavily reliant on fertilizers and pesticides. Verified platforms offering supply chain solutions and regional networking are instrumental in facilitating this growth. Aritral, as an AI-driven trade facilitator, streamlines commodity exchanges, providing transparency and efficiency in nitrogen and related chemical trades.

-

Oxygen Trade Dynamics in Middle East & West Asia

Oxygen, a vital commodity in both medical and industrial contexts, plays a significant role in the Middle East"s expanding trade network. As the region increasingly focuses on diversifying its economies, the medical and industrial oxygen gas marketplace has seen substantial growth. Industrial oxygen gas, primarily used in steel manufacturing, chemical oxidation, and wastewater treatment, is essential for infrastructure development, making it a key input in West Asia’s industrial supply chains. The Middle East also serves as a hub for the medical oxygen market, driven by rising healthcare demand and pandemic preparedness. In commodity trade, verified exporters and importers on B2B marketplaces across West Asia and the Middle East have streamlined oxygen gas transactions, ensuring quality standards and reliable supply chains. Platforms like Aritral enable regional product listings and trade advertising, connecting suppliers with buyers efficiently. Market insights reveal that the region"s commitment to industrialization and healthcare expansion underpins oxygen"s growing demand. Complementing the oxygen market are other chemicals like sulfuric acid, phosphoric acid, ammonia, chlorine, nitrogen, and their applications in fertilizers, detergents, and pesticides.

Sulfuric acid, for instance, is pivotal in fertilizer production, while ammonia plays a significant role in agricultural and industrial applications. These chemicals collectively shape the commodity trade landscape and enhance supply chain solutions in the Middle East. As countries in West Asia invest in infrastructure and agriculture, oxygen, along with these chemicals, is crucial for sustainable growth. The cross-border nature of these trades highlights the importance of robust B2B platforms, such as Aritral, to address challenges like verification, market access, and logistics. By fostering business networking and providing regional product listings, these platforms ensure seamless integration into global supply chains. "

-

Phosphoric Acid Trade Insights in West Asia and Middle East

Phosphoric acid, an essential chemical compound, plays a pivotal role in industrial applications such as fertilizers, detergents, and pesticides. The Middle East and West Asia have emerged as critical hubs in the global trade of phosphoric acid, driven by their strategic location and robust supply chains. Phosphoric acid production is closely tied to sulfuric acid and ammonia, which are integral to the manufacturing process and regional chemical markets. The commodity trade in the Middle East benefits from verified exporters and importers on B2B marketplaces that streamline transactions and foster business networking. Phosphoric acid is primarily used in agriculture, where it serves as a key ingredient in fertilizers. The growing focus on food security in West Asia and the Middle East has heightened the demand for agricultural chemicals, including phosphoric acid, ammonia, and sulfuric acid. In addition to agriculture, phosphoric acid is extensively applied in detergents, contributing to hygiene markets in Asia and the Middle East. Trade platforms such as Aritral simplify commodity transactions by offering supply chain solutions, verified listings, and market insights.

The integration of AI-powered tools assists businesses in navigating market trends and connecting with trusted exporters and importers across Southwest Asia. The phosphoric acid market in West Asia is impacted by regional dynamics, including import-export regulations and the availability of raw materials like sulfuric acid. Manufacturers in West Asia leverage their proximity to natural resources and established logistics networks to maintain a competitive edge in the global market. As demand grows for agricultural and industrial chemicals, B2B marketplaces are facilitating trade advertising and fostering collaborations among key stakeholders in the chemical sector.

-

Sulfuric Acid Trade in the Middle East and West Asia

Sulfuric acid is a cornerstone of the global chemicals industry, influencing a broad spectrum of sectors such as fertilizers, detergents, and industrial processing. In the Middle East and West Asia, the sulfuric acid market has grown significantly due to its extensive applications in agriculture and manufacturing. The region is a major producer and exporter, leveraging its proximity to raw materials like sulfur, as well as robust supply chains driven by B2B platforms and trade networks. Sulfuric acid plays a critical role in the production of fertilizers, particularly phosphoric acid-based fertilizers, which are vital for the agricultural needs of West Asia. Verified exporters and importers in the region rely on Middle Eastern trade platforms to ensure seamless transactions and efficient supply chain solutions. Additionally, trade advertising platforms and regional product listings facilitate transparency and market insights, enabling businesses to navigate the commodity trade landscape effectively. Other key chemicals such as chlorine, nitrogen, ammonia, and oxygen are essential to Middle Eastern industries, with chlorine and nitrogen holding significant value in industrial and agricultural processes. For instance, ammonia’s role in fertilizer production and chlorine’s use in water treatment exemplify how these chemicals shape commodity trade dynamics in the Persian Gulf.

The detergent market also benefits substantially from sulfuric acid, with its applications in surfactant production driving growth in the hygiene market of West Asia. B2B marketplaces in Asia are instrumental in connecting buyers and sellers, fostering business networking, and bridging global supply chains for agricultural and industrial needs. Aritral, an AI-driven B2B platform, simplifies international trade in commodities like sulfuric acid by offering product listings, direct communication tools, and AI-powered marketing solutions. This innovation promotes a seamless trading experience and supports the growing demand for chemicals in the region.

-

Applications of Ammonia

Ammonia is crucial in various sectors, primarily as a nitrogen source for fertilizers, enhancing agricultural productivity through the Haber-Bosch process. It is also a key precursor in producing industrial chemicals like nitric acid and hydrogen cyanide, which are essential for manufacturing plastics and pharmaceuticals. In refrigeration, ammonia"s efficiency makes it a preferred choice for large-scale cooling systems. Additionally, it serves as an effective cleaning agent in household products and plays a significant role in metal surface treatment. Ammonia"s potential as a renewable energy source is gaining attention due to its high hydrogen content, making it suitable for fuel cells. Furthermore, ammonia is vital in water treatment processes for pH control and disinfection. Its historical significance is notable; the mass production of ammonia has significantly impacted global food security by preventing starvation for billions. However, its production also raises environmental concerns due to pollution.

-

History of Ammonia

Ammonia has been utilized since ancient times, initially recognized in various forms such as vapors from animal waste. Its distinct properties were studied during the alchemical period, where it was referred to as "spirits of hartshorn. " The isolation of ammonia as a pure compound occurred in the 18th century when Carl Wilhelm Scheele obtained a colorless gas from heating sal ammoniac. Antoine Lavoisier later named it "ammonia" in 1782. The development of the Haber-Bosch process in the early 20th century marked a significant advancement, allowing for large-scale production of ammonia from nitrogen and hydrogen gases. This innovation made ammonia essential for producing nitrogen-based fertilizers, significantly boosting agricultural yields. Ammonia"s applications extend beyond agriculture to industries such as chemicals and refrigeration. Historical uses include its role as currency in ancient Rome and its early identification by Jabir Ibn Hayyan in the 8th century.

Various production methods exist globally, with natural gas being the primary feedstock for ammonia synthesis today. "

-

Ammonia production in the Middle East

West Asia, particularly countries like Saudi Arabia, Qatar, Iran, and the UAE, has emerged as a key player in ammonia production. These nations have heavily invested in infrastructure to support large-scale ammonia facilities, primarily utilizing natural gas as feedstock due to the region"s abundant reserves. The production process involves steam methane reforming, where methane is converted into hydrogen and then combined with nitrogen to create ammonia. While this industry contributes significantly to economic growth and diversification, it also raises environmental concerns due to greenhouse gas emissions associated with traditional production methods. Efforts are underway to adopt cleaner technologies such as renewable energy sources and carbon capture systems. The Middle East produces over 15 million tons of ammonia annually, with a substantial portion exported to global markets in Asia, Europe, and Africa. Saudi Arabia leads production capacity at 3. 5 million tons, followed closely by Iran and Qatar.

The integration of ammonia production with downstream industries like urea manufacturing enhances the region"s competitiveness in the fertilizer market. As global demand for chemical fertilizers rises due to population growth, West Asian countries are well-positioned to meet this need while exploring sustainable practices.

-

What is Ammonia?

Ammonia (NH3) is a colorless gas composed of nitrogen and hydrogen, known for its pungent odor and high solubility in water. It is produced primarily through the Haber-Bosch process, which combines nitrogen and hydrogen under specific conditions. Ammonia has diverse applications, including use as a cleaning agent, in fertilizers, and as a precursor for various chemicals such as plastics and pharmaceuticals. Its role in agriculture is significant, providing essential nitrogen for plant growth. However, ammonia must be handled with care due to its toxic nature; inhalation can lead to respiratory issues and irritation. Environmental concerns arise from improper disposal or excessive release into water bodies, which can harm aquatic life. Ammonia also serves as a refrigerant due to its efficient heat transfer properties and is increasingly recognized as a potential alternative energy source due to its high energy density. The compound"s versatility makes it integral to multiple industries while necessitating strict safety measures during handling. "