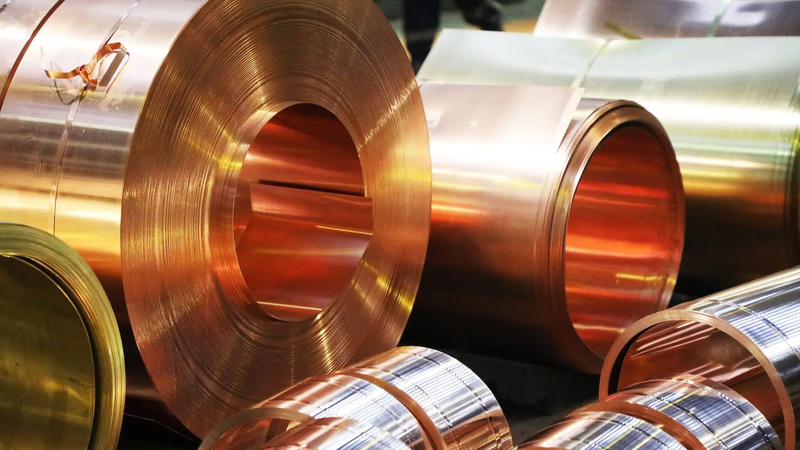

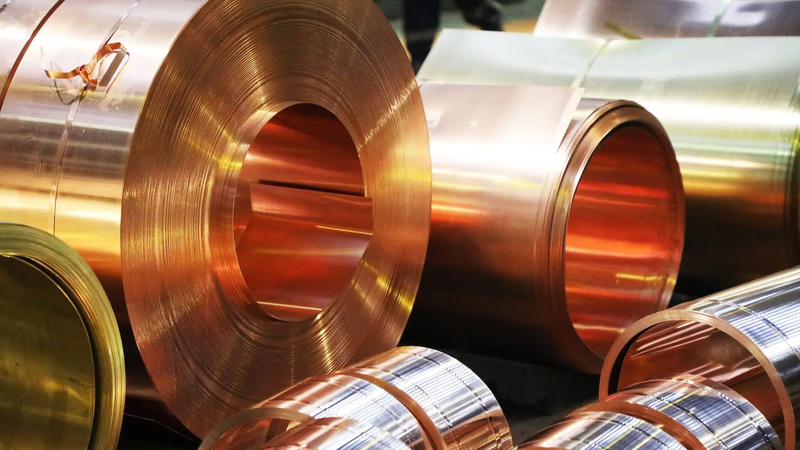

Copper alloys like bronze and brass are essential in trade.

Bronze is an alloy of copper and tin, but other elements such as aluminum, phosphorus, or silicon can also be added. It is known for its strength, durability, and resistance to corrosion. Bronze has been used for casting sculptures, making musical instruments, and producing bearings, gears, and coins. Brass is an alloy of copper and zinc, but other elements like lead, tin, or aluminum may be added for specific purposes. It is valued for its attractive golden appearance, malleability, and acoustic properties. Brass is used in musical instruments, plumbing fittings, decorative items, and electrical connectors.

Cupronickel is an alloy of copper and nickel, with varying compositions depending on the desired properties. It exhibits excellent resistance to corrosion in seawater and is commonly used for marine applications, such as shipbuilding, offshore structures, and heat exchangers. Cupronickel is also used in coinage and electrical components. These alloys, also known as nickel silvers or German silvers, are composed of copper, nickel, and zinc. They resemble silver in appearance and are commonly used in jewelry, silverware, musical instruments, and electrical connectors.

1- Pure copper: which contains 99.3% or more copper.

2 - Alloys with a high percentage of copper: have a percentage of copper between 96% to 99.3% and to achieve special properties, silver may be added.

3- Brass: It has zinc as the main alloying element, also other elements such as iron, aluminum, nickel, and silicon are added to improve the properties of the alloy. Brass has high corrosion resistance and tensile strength.

Brass additives

Adding lead to brass metal compounds can improve machining properties, as well as reduce tool wear. Adding aluminum, iron, and manganese to rice increases strength, adding silicon improves abrasion resistance.

Classification of brasses

- Alpha brass, with a zinc content of less than 37%. These alloys are ductile and can be cooled.

- Alpha-beta or binary brass contains 37-45% zinc. These alloys have a more limited ductility and are harder and stronger.

Brass metal families:

- CU-Zn alloys

- CU-Zn-Pb alloys (leaded brass)

- Cu-Zn-Sn alloys (tin brass)

4 - Bronzes: have tin as the only alloying element or the main alloying element. Today, bronze refers to copper alloys whose main alloy element is other than nickel and zinc.

The bronze family includes:

- Cu-Sn-P alloys (phosphor bronzes)

- CU-Sn-Pb-P alloys ((lead phosphor bronze)

- Cu-Al alloys ((aluminum bronze)

- CU-Si alloys ((silicon bronzes)

5 - Other alloy groups

- CU-Ni alloys: As the name implies, the main alloying element is nickel. This group can include other alloying elements or nickel alone.

- CU-Ni-Zn alloys: These alloys are known as nickel silver due to the color of the alloy. This group contains zinc and nickel as the main alloying elements, and other alloying elements may also be added.

Leaded Copper: Lead copper is a cast copper alloy that contains 20% or more lead additive. They also contain small amounts of silver but no trace elements or zinc.

6- Special alloys: When alloys contain chemical compounds that do not fall into any of the above groups, they are called special alloys.

Copper-aluminum alloys, such as aluminum bronze or aluminum brass, combine copper with aluminum. These alloys possess high strength, corrosion resistance, and thermal conductivity. They find applications in marine environments, heat exchangers, and various industrial components. Copper-silver alloys, known as silvered copper or coin silver, are blends of copper and silver. They were historically used for making coins, cutlery, and decorative items. These alloys can exhibit enhanced antimicrobial properties due to the presence of silver.

Copper-beryllium alloys, also called beryllium copper, contain copper with a small percentage of beryllium. These alloys possess high strength, hardness, and electrical conductivity. They are used in electrical connectors, springs, switches, and other applications requiring excellent mechanical and electrical properties.

-

Copper recycling significantly conserves natural resources by reducing the need for new mining and extraction, thus preserving valuable copper ore reserves. The process requires 85-90% less energy than primary production, leading to lower greenhouse gas emissions and a reduced carbon footprint. Recycling also diverts copper waste from landfills, minimizing environmental pollution. The industry creates jobs in collection, sorting, processing, and manufacturing recycled copper, contributing to economic growth. Various sources of recyclable copper include wiring from electronics, pipes, fittings, and even discarded coins. The recycling process involves sorting, shredding, melting, and purifying to produce new copper products or alloys. Approximately 40% of annual copper alloy consumption comes from recycled materials. Copper"s properties such as high electrical and thermal conductivity make it essential in various applications including electrical transmission and heat exchangers.

Its corrosion resistance further enhances its utility across industrial sectors. "

-

Copper ingots are primarily produced through smelting and casting, where copper ore is extracted, processed, and refined. The smelting process involves heating concentrated copper ore with fluxes in a furnace to separate impurities, resulting in molten copper. This molten metal is then poured into molds to solidify into ingots. An alternative method for producing copper ingots is electrolytic refining, which uses an acidic copper sulfate solution to deposit copper ions onto a cathode through electrolysis. Copper ingots come in various grades, with purity levels ranging from 99. 95% to 99. 99%. These ingots serve as a fundamental form of copper for manufacturing products and alloys.

Additionally, recycling processes can convert scrap copper into new ingots by shredding and smelting used materials like wiring and pipes. Copper has historical significance dating back to ancient civilizations and remains vital in modern applications due to its excellent conductivity and malleability.

-

The Middle East and West Asia exhibit a robust demand for copper, driven by urbanization, construction, and industrial growth. Key countries like Saudi Arabia, Iran, Turkey, and the UAE are experiencing significant infrastructure development that necessitates large quantities of copper for electrical wiring and plumbing systems. Despite having some mining operations, the region remains a net importer of copper, relying on imports from major producers such as Chile and Peru. Dubai and Istanbul serve as crucial trading hubs for copper distribution. The rise in population and disposable incomes has further increased the demand for electrical devices, making copper essential in manufacturing components like transformers and motors. Additionally, the region is witnessing a growing emphasis on copper recycling to promote sustainability. Global copper prices significantly influence the local market dynamics, affecting profitability across various industries. While the high cost of copper compared to alternatives like aluminum can deter some users, its superior conductivity and safety make it a preferred choice in electrical applications. The ongoing industrial expansion across sectors such as construction and automotive continues to drive copper consumption in this region.

-

Copper toxicity can occur from excessive consumption or inhalation, leading to symptoms like nausea, abdominal pain, and severe organ damage. Acute cases are rare and often linked to occupational exposure or accidental ingestion. Wilson"s disease, a genetic disorder affecting copper metabolism, results in copper accumulation in organs, necessitating treatment to reduce intake and eliminate excess copper. Allergic reactions to copper may arise from skin contact, causing irritation or dermatitis. Copper"s antimicrobial properties have led to its use in medical settings to reduce infection risks. Recent advancements include a bioactive implant that combines collagen with copper particles, significantly reducing bacterial populations and enhancing bone growth. This innovative approach offers a potential one-step treatment for bone infections without antibiotics. While copper is essential for various bodily functions, excessive exposure can lead to health issues.

Its traditional medicinal uses are often unsupported by scientific evidence, although some claim benefits for arthritis relief. The metal"s ability to inhibit microbial growth has prompted its application in hospital environments to combat infections. "

-

Copper is a vital transition metal, known for its high electrical and thermal conductivity. It has been utilized since ancient civilizations, marking the beginning of the Bronze Age. Found in various minerals, copper is primarily extracted from ores through mining processes. Its applications span across electrical wiring, plumbing, and architecture, making it the third most widely used industrial metal globally. The majority of copper consumption is attributed to electrical applications, with significant recycling potential that enhances its sustainability. Copper alloys like bronze and brass exhibit improved properties, further expanding its utility. Additionally, copper"s antimicrobial properties make it valuable in medical settings. However, the environmental impact of copper mining necessitates sustainable practices to mitigate habitat destruction and pollution. "

-

Copper and its alloys, including bronze, brass, and cupronickel, play a significant role in various industries due to their unique properties. Bronze, an alloy of copper and tin, is known for its strength and corrosion resistance, making it ideal for sculptures and mechanical components. Brass, primarily composed of copper and zinc, is valued for its malleability and attractive appearance, commonly used in musical instruments and plumbing fittings. Cupronickel combines copper with nickel to enhance corrosion resistance in marine applications. Other notable alloys include leaded brass for improved machining properties and special alloys like aluminum bronze that offer high strength and thermal conductivity. The classification of these alloys is based on their composition, with variations such as alpha brass (less than 37% zinc) and phosphor bronzes that include additional elements for enhanced performance. Understanding these types of copper alloys is crucial for businesses engaged in import-export activities within the Middle East trade platform.

-

Copper is a vital metal extensively used across various industries, particularly in electricity and construction. Its excellent conductivity makes it the preferred choice for electrical wiring, power cables, and electronic devices. The electricity sector is the largest consumer of copper due to its efficiency in transmitting electricity. Additionally, copper"s strength and resistance to corrosion enhance its suitability for motors and converters. In telecommunications, copper remains essential for high-speed data transmission despite advancements in fiber optics. The metal"s versatility extends to building construction, where it is utilized in plumbing, roofing, and heat transfer systems. Its recyclability adds an environmental benefit, allowing for sustainable practices in construction. Copper"s unique properties also contribute to safety; it does not burn or release harmful gases during fires and helps prevent bacterial growth in water supply systems. Overall, copper"s multifaceted applications underscore its importance in modern infrastructure and technology.